Mining Mill Waste Sand Recodition

.jpg)

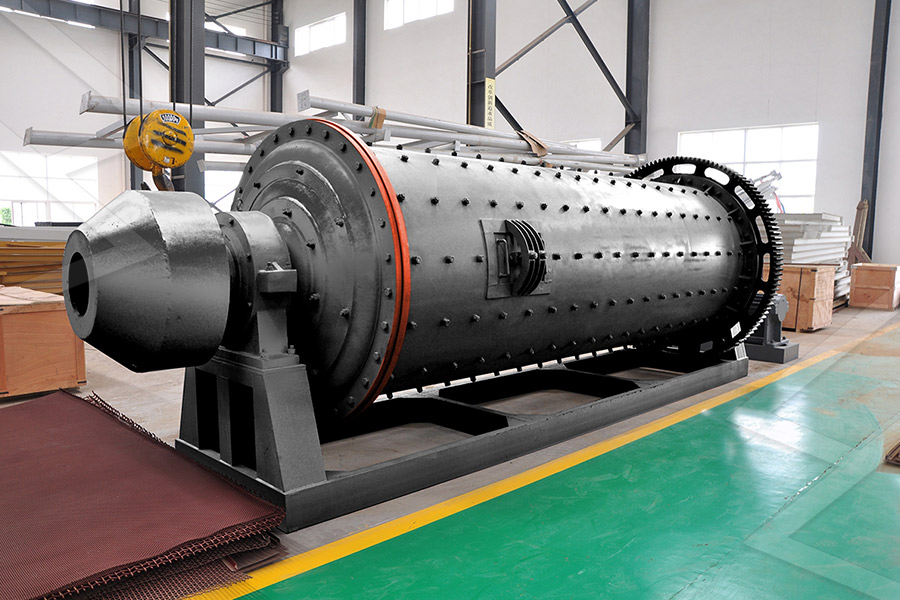

A detailed review study on utilization of mine and industrial

2024年3月13日 Deep underground mining has increased as a result of the lack of economic minerals close to the surface of the ground Mining companies are now thinking of backfilling 2022年2月15日 Waste generated due to mining activity poses a serious issue due to the large amounts generated, even up to 65 billion tons per year, and is often associated with the risk Waste management in the mining industry of metals ores, 2024年11月13日 Producing sand from mining waste is a sustainable and economically viable solution to the challenges posed by natural sand extraction With the right equipment and Sand Production Process Of Mining Waste Eastman Rock 2021年7月2日 In this study, we present a critical overview of solid wastes in mining and the optimal waste management strategy including legal remedies and economic constraints A A Sustainable Approach to Transforming Mining Waste into 2015年8月1日 For the effective and integrated rehabilitation of mining wastes, it is important to understand the petrology and structural geology, geological texture, mineralization type, Sustainable rehabilitation of mining waste and acid mine The goal of this study was to examine the dynamics of mining waste research and novel methods/techniques for the remediation of mining waste residues Significant waste is Novel Methods and Techniques for the Remediation of Mining Waste

The regeneration of waste foundry sand and residue

2012年2月15日 The processes for recycling waste foundry sand are divided between regeneration and beneficial reuse, and the potential for regeneration is higher than that of 2014年10月28日 Several promising avenues for the management and remediation of mine wastes are outlined in this special issue Due to increasing amounts of mine wastes generated Mine Waste Characterization, Management and Remediation 2012年8月10日 Residual mining wastes after reuse or resource recovery are typically discarded at specific sites such as tailing ponds If wastes are not disposed of properly, wastewaters, especially from hydrocarbon wastes, can The Challenges of Reusing Mining and Mineral Central Florida's Leading Industrial Supplier since 1909! With over 100,000 square feet of inventory, more than 7,500 SKUs, and competitive prices, we deliver fast, reliable service to meet the needs of projects of all sizesHome Page [minemill]1 天前 The Regulations (R8910 through R89350) were promulgated to better define how to enact the Mining Act These two documents create protections for the surrounding environment and require reclamation of land affected by Mining and Reclamation South Carolina 19 小时之前 12 Solid Mining Waste 13 Purpose 14 Document Organization 2 Mining and Mining Waste 2 Mining and Mining Waste 21 Status and Future of the Global Mining Industry 22 Common Mined Minerals 23 Common Types of Mining Waste 24 Mining Waste Hazard Reduction 25 Potential Radioactivity in Mining Waste 3 Solid Mining Waste Reuse 6 Project Summaries and Case Studies – Reuse of Solid Mining Waste

.jpg)

Reconciliationprinciplesfortheminingindustry Mining

2019年11月30日 usually relates received at mill (measured by the mill) tonnages, grades and metal content to delivered to mill production tonnages, grade and metal content The F3 factor is F16F2 and Table 1 Production schedule and cash flow statement for copper mine Input variable Mining ore/$/t 2 00 Mining waste/$/t 2 00 Milling/$/t 5 年1月1日 Tailings, or waste material, are then deposited in a tailings storage facility (TSF) Any rock removed from the mine with no economic value, or waste rock, is stored without being processed Most mills use wet processes, such as froth flotation, in order to separate valuable minerals from the nonvaluable minerals in the oreReducing mine water requirements ScienceDirect2018年7月2日 Growing social awareness of the need to adequately treat mining waste in order to protect the environment has led to an increase in the research in this field The aim of this study was to analyze the dynamics of the research focused on mining waste and its sustainable management on a worldwide scale from 1988 to 2017 A systematic review and a bibliometric Mining Waste and Its Sustainable Management: Advances in MDPI2010年1月1日 The term mine waste implies that the material has no current economic value and is an unwanted byproduct of mining However, some mine wastes can be useful and this has been recognized since the beginning of mining and smelting For example, the use of slag in road construction can be traced back to the very early days when the Romans used iron slag as a Introduction to Mine Wastes SpringerLink2024年11月13日 Environmental Impact: Improper management of mining waste can lead to soil, water, and air pollution Recycling this waste into sand can significantly reduce environmental harm Economic Potential: Transforming mining waste into sand can create new revenue streams for mining companies, turning what would be waste into a valuable resourceSand Production Process Of Mining Waste Eastman Rock 2011年1月1日 Mine wastes and their environmentally acceptable storage constitute the largest waste problem on the planet Mine wastes have been accumulating for thousands of years, and their rate of production has accelerated in step with increases of the human population to an estimated worldwide production rate of 350 × 10 9 ta1If collected and spread in a uniform Mine Waste: A Brief Overview of Origins, Quantities, and

.jpg)

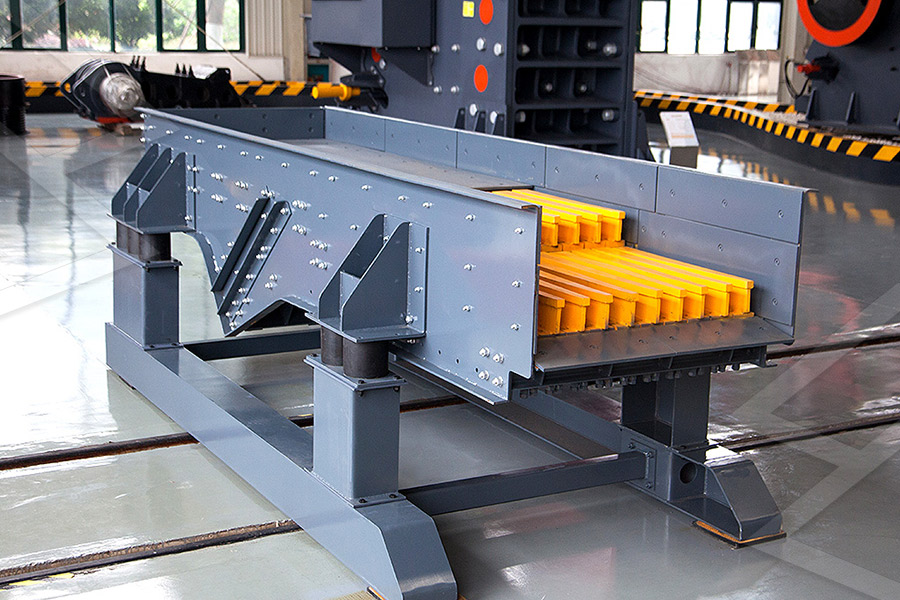

Innovations in Mine Waste Management and Recycling

2024年9月18日 the advancements in mine waste management and recycling reflect a significant shift towards sustainable practices within the mining industry As environmental concerns continue to intensify, the integration of innovative technologies and strategies not only mitigates the negative impacts of mining activities but also promotes the 2022年9月1日 The path towards repurposing or reprocessing of the mining waste is only viable when the technological readiness level has reached tangible maturity, but until then the industry must apply duty of care (Boswell Sobkowicz, 2011) and best practice to manage it either by containment in waste deposits (eg, tailings storage facilities Towards waterless operations from mine to mill ScienceDirect2021年7月2日 Mineral waste can be defined as a material leftover from exploration, mining and quarrying operation that cannot find a productive use It is the highvolume material that originates from the excavation and physical and chemical processing of a wide range of metalliferous and nonmetalliferous minerals by opencast and deep shaft methods []The mine waste is the A Sustainable Approach to Transforming Mining Waste into 2025年3月1日 Sand mining is a process of extracting sand mainly through openpit mining in different geomorphic settings, such as riverbeds, beaches, inland dunes in coastal areas, or shallow ocean surfaces [3]Historically, sand mining was within the replenishment limits of rivers; however, the steep demand increase for industrial development has severely affected river A review of river sand mining: Methods, impacts, and 2019年1月1日 Mine wastes and their environmentally acceptable storage constitute the largest waste problem on the planet Mine wastes have been accumulating for thousands of years, and their rate of production has accelerated in step with increases of the human population to an estimated worldwide production rate of 350 × 10 9 t year − 1If collected and spread in a Mine Waste: A Brief Overview of Origins, Quantities, and 2016年1月1日 If above ground mining and mill waste disposal are unavoidable (completely or partly), the use of appropriately designed multicomponent/layered covers over the facility is best practice Near surface disposal in the vicinity of a mine and mill can pose serious engineering challenges depending on the geomechanical and physical and chemical Uranium mine and mill remediation and reclamation

.jpg)

Mining and milling ScienceDirect

2020年1月1日 The nuclear fuel cycle is a multistage industrial process revolving around the utilization of uranium to produce electricity and is depicted in Fig 81The frontend of the fuel cycle begins with mining uranium out of the ground, milling it into a more concentrated form (eg, U 3 O 8), converting it either into a useable form for enrichment for light water reactors (LWR; Minetomill integration Subsequently, as mining progresses, more waste would be included in the muck piles and the mill feed grade would decrease A grade of 246% gold was reported in January, decreasing to 130% in December In this way dilution can be measured and can be controlled by reducing external waste The financial impact of Monitoring ore loss and dilution for minetomill integration 3 天之前 No 1 source of global mining news and opinion Lithium April 04, 2025 03:49 am Kodal Minerals nears commercial production at Mali lithium No 1 source of global mining news and 2025年3月27日 Figure 23Major phases of the mining process Source: Stephanie Aurelius, Geosyntec 23 Common Types of Mining Waste Generally, mining and metallurgical wastes are heterogeneous materials that can include ore, gangue, industrial minerals, metals, coal or mineral fuels, rock, loose sediment, mill tailings, metallurgical slag, roasted ore, flue dust, ash, and 2 Mining and Mining Waste – Reuse of Solid Mining Waste2018年3月12日 Mining and metallurgical processes produce significant amounts of waste In South Africa, mining and metallurgical wastes constitute one of the biggest challenges to the environment(PDF) Mining and metallurgical wastes: a review of2017年12月19日 How to plan for your maintenance shutdown When planning maintenance shutdowns, first identify outstanding maintenance and inspection tasks These will include regular tasks (shaft alignments, journal inspections, Mill maintenance – 3 simple ways to keep your

.jpg)

Integration of MinetoMill Production Planning Strategy for Oil Sands

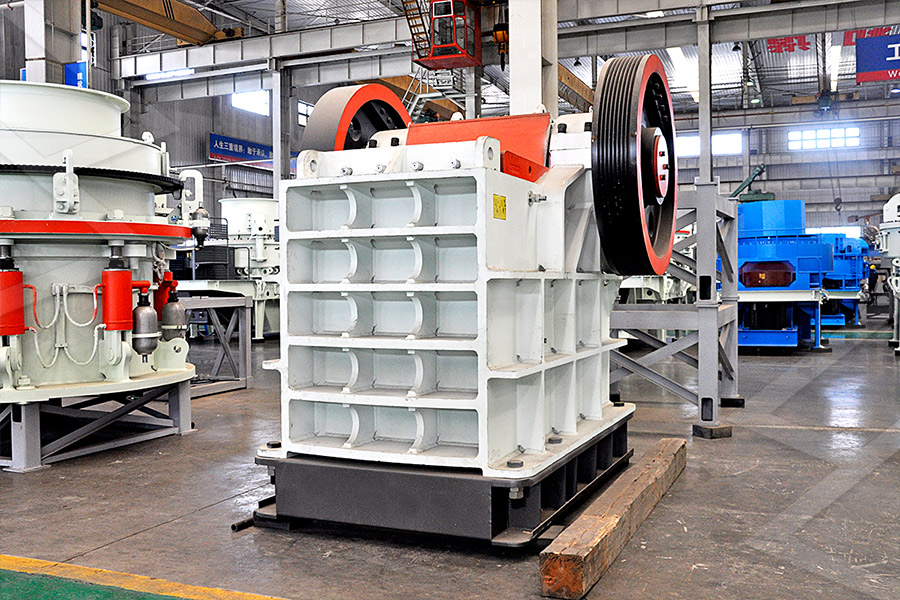

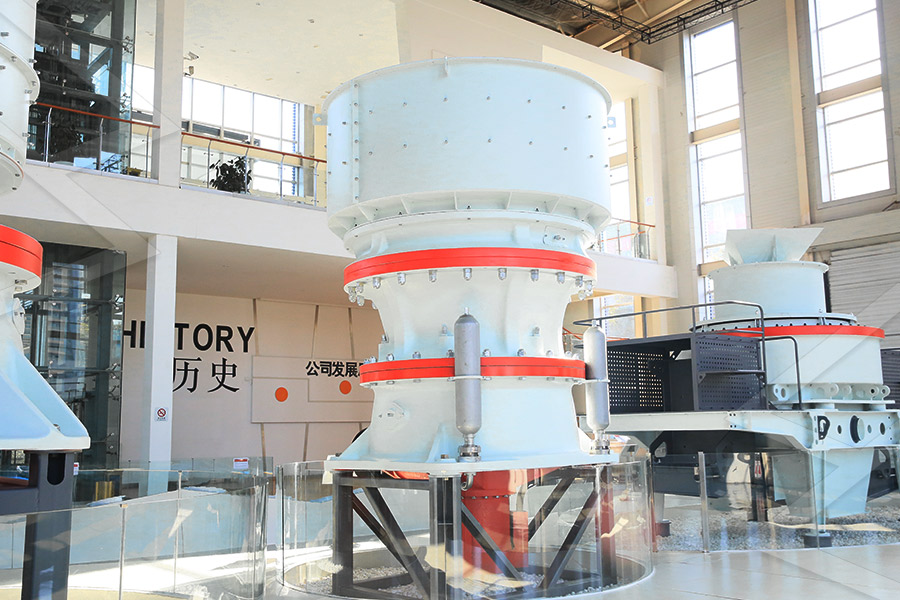

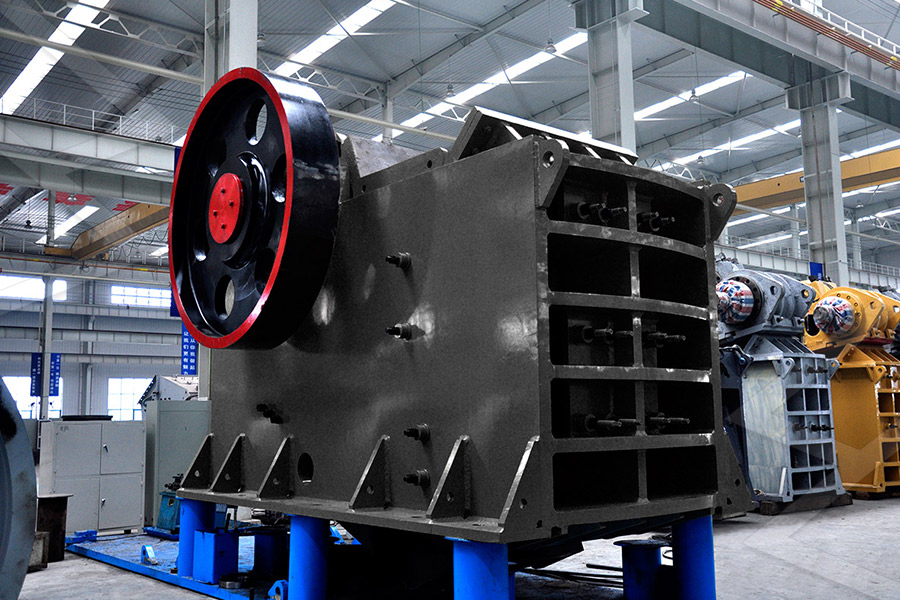

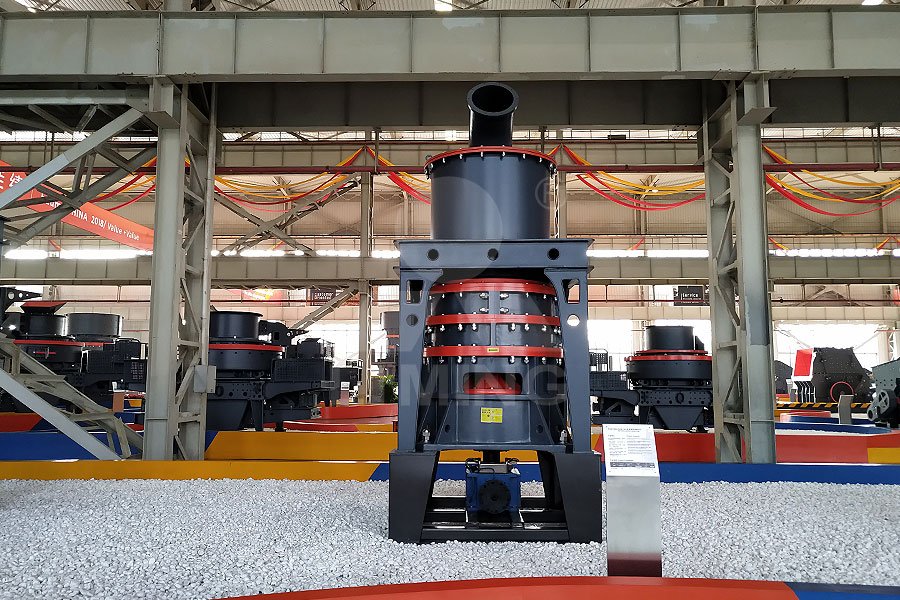

INTEGRATION OF MINETOMILL PRODUCTION PLANNING STRATEGY FOR OIL SANDS MINING AND WASTE DISPOSAL Authors: Ahlam R Maremi and Eugene BenAwuah December 10, 2018 Outline v Oil sands mining and waste management; v Problem definition; v Objectives; v Methodology – MILGP model; v Implementation of the MILGP model with two case studies; v 2017年6月2日 Table Source: Wikipedia (Crushers) Cone crushers use a spinning cone that gyrates in the bowl in an eccentric motion to crush the rock between the cone surface, referred to as the mantle, and the crusher bowl How it Works: Crushers, Grinding Mills and 3 天之前 The main types of waste generated by the mining and milling of uranium ore are tailings and waste rock Tailings are the waste produced by grinding the ore and the chemical concentration of uranium When dried, tailings have the consistency of fine sand Waste rock is simply rock material removed from the mine to gain access to the oreUranium mines and mills waste cnscccsngcca2018年5月1日 Thus, waste foundry sand, if untreated, poses a threat to both environment and life According to a report by Coastal regulation zone notification Ministry of environment and forests (2011), the government of India has banned sand mining in many places which have resulted in a sharp increase in the cost of fresh sand availableReclamation of used green sand in small scale foundries2025年2月26日 Oresand offers us a rare chance to tackle two hard environmental problems at once, by slashing the staggering volume of mining waste and reducing the need for potentially dangerous tailings dams Nosetotail mining: how making sand from ore could solve 2018年9月4日 Integration of MinetoMill Production Planning Strategy for Oil Sands Mining and Waste Disposal Ahlam Maremi and Eugene BenAwuah Mining Optimization Laboratory (MOL) Laurentian University, Sudbury, Canada ABSTRACT For oil sands mining, the production schedule must be integrated simultaneously with inpit and exIntegration of MinetoMill Production Planning Strategy

.jpg)

"Integration of minetomill production planning strategy for oil sands

2018年12月9日 In achieving maximum benefit in oil sands mining, the time and sequence of removing ore, dyke material and waste from the final pit limit is essential to the longterm production schedule2014年10月28日 Mining is a vital part of the Global economy, but the extraction of metals, metalloids, and other mineral products generates vast quantities of liquid and solid waste Currently the volume is estimated at several thousand million tons per annum, but is increasing exponentially as demand and exploitation of lowergrade deposits increases The high Mine Waste Characterization, Management and Remediation 2022年2月15日 Inplant production of bricks containing waste foundry sand—a study with Belgaum foundry industry Case Stud Constr Mater (2018) Utilisation of lead–zinc mill tailings and slag as paste backfill materials Environ Earth Sci (2020) Mining waste valorization may offer environmental advantages over traditional makewastedispose Waste management in the mining industry of metals ores, Central Florida's Leading Industrial Supplier since 1909! With over 100,000 square feet of inventory, more than 7,500 SKUs, and competitive prices, we deliver fast, reliable service to meet the needs of projects of all sizesHome Page [minemill]1 天前 The Regulations (R8910 through R89350) were promulgated to better define how to enact the Mining Act These two documents create protections for the surrounding environment and require reclamation of land affected by Mining and Reclamation South Carolina 19 小时之前 12 Solid Mining Waste 13 Purpose 14 Document Organization 2 Mining and Mining Waste 2 Mining and Mining Waste 21 Status and Future of the Global Mining Industry 22 Common Mined Minerals 23 Common Types of Mining Waste 24 Mining Waste Hazard Reduction 25 Potential Radioactivity in Mining Waste 3 Solid Mining Waste Reuse 6 Project Summaries and Case Studies – Reuse of Solid Mining Waste

.jpg)

Reconciliationprinciplesfortheminingindustry Mining

2019年11月30日 usually relates received at mill (measured by the mill) tonnages, grades and metal content to delivered to mill production tonnages, grade and metal content The F3 factor is F16F2 and Table 1 Production schedule and cash flow statement for copper mine Input variable Mining ore/$/t 2 00 Mining waste/$/t 2 00 Milling/$/t 5 年1月1日 Tailings, or waste material, are then deposited in a tailings storage facility (TSF) Any rock removed from the mine with no economic value, or waste rock, is stored without being processed Most mills use wet processes, such as froth flotation, in order to separate valuable minerals from the nonvaluable minerals in the oreReducing mine water requirements ScienceDirect2018年7月2日 Growing social awareness of the need to adequately treat mining waste in order to protect the environment has led to an increase in the research in this field The aim of this study was to analyze the dynamics of the research focused on mining waste and its sustainable management on a worldwide scale from 1988 to 2017 A systematic review and a bibliometric Mining Waste and Its Sustainable Management: Advances in MDPI2010年1月1日 The term mine waste implies that the material has no current economic value and is an unwanted byproduct of mining However, some mine wastes can be useful and this has been recognized since the beginning of mining and smelting For example, the use of slag in road construction can be traced back to the very early days when the Romans used iron slag as a Introduction to Mine Wastes SpringerLink2024年11月13日 Environmental Impact: Improper management of mining waste can lead to soil, water, and air pollution Recycling this waste into sand can significantly reduce environmental harm Economic Potential: Transforming mining waste into sand can create new revenue streams for mining companies, turning what would be waste into a valuable resourceSand Production Process Of Mining Waste Eastman Rock 2011年1月1日 Mine wastes and their environmentally acceptable storage constitute the largest waste problem on the planet Mine wastes have been accumulating for thousands of years, and their rate of production has accelerated in step with increases of the human population to an estimated worldwide production rate of 350 × 10 9 ta1If collected and spread in a uniform Mine Waste: A Brief Overview of Origins, Quantities, and

.jpg)

Innovations in Mine Waste Management and Recycling

2024年9月18日 the advancements in mine waste management and recycling reflect a significant shift towards sustainable practices within the mining industry As environmental concerns continue to intensify, the integration of innovative technologies and strategies not only mitigates the negative impacts of mining activities but also promotes the