Smelter Process For Recovery Of Gold

.jpg)

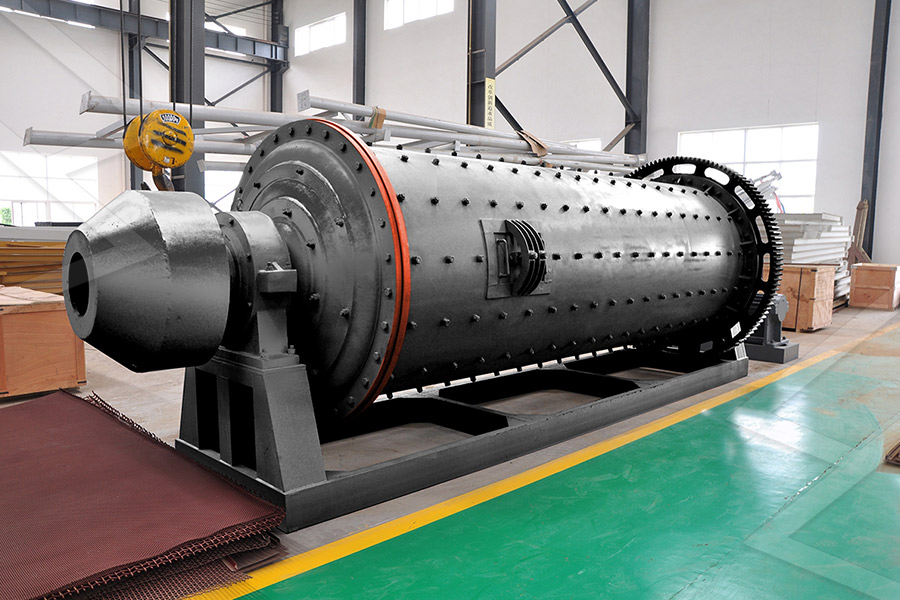

Processing technologies for goldtelluride ores 911

2024年9月24日 In a modern gold processing plant, the recovery can be up to 98% with the aid of the latest concentration and smelting techniques A successful gold recovery strategy relies Thus, the bulk of the gold may be recovered by leaching techniques using cyanidation or aqueous chlorination, and the residue may then be treated by smelting to recover the balance Gold processing Refining, Smelting, Purifying Britannica2005年1月1日 Gold is mostly recovered in copper smelters and the processes to recover gold from refinery anodic slimes are varied; just a few typical examples have been presented in this Recovery of gold as byproduct from the basemetals industries2024年12月7日 This paper aims to analyze systematically and, for the first time, provide estimates of gold firstpass recovery rates across various operational units within the copper sulfide concentrate processing flow sheet It also Gold Recovery from Smelting Copper Sulfide 2017年1月18日 Gold recovered from the ore by the MerrillCrowe process or by the elecrowinning method is likely to contain traces of mercury To remove these traces of mercury from the gold you must heat it in a retortThe Gold Smelting Process Melting, Smelting2024年5月14日 The processing of gold copper and copper gold ores can be highly problematic, site specific and the process selection is dependent on ore grade, mineralogy, acid leach Flowsheet Options For Processing Copper Gold Gold

.jpg)

Recovery of Gold as ByProduct from the BaseMetals Industries

2016年1月1日 Recovery of gold from electronic scrap and other industrial wastes is increasingly practiced New hydrometallurgical processes have also been developed to recover gold [1] Gold production is commonly done by the amalgamation and cyanidation process However, due to the increased complexity of the polymetallic gold ore, the direct cyanidation process Process Development for Gold Concentrate Recovery by 2021年11月2日 process 33 Gold and Silver Deportment in CESL Copper Process Gold and silver generally do not leach in the CESL Copper Process, and are therefore left almost quantitatively in the residue after recovery of base metals Thus any recovery process for gold and silver must be an additional or subsequent step(s) processing suchTHE NEW CESL GOLD PROCESS Teck Resources2017年9月7日 At current gold prices this is worth about US$600 Both smelter treatment charges and oxidation or bioleach costs are at least $200/t of concentrate and payables/recovery in the 90% range, so a minimum GSR for Gold processing 101 Mining Magazine2020年11月1日 The mineral resources containing SPMs are of many types and variable grade, resulting in high mining and utilization costs (Işıldar et al, 2017; Rana et al, 2020)Further, > 99% of these resource exist in only a few countries, such as South Africa and Canada (Zhang et al, 2017a)As a result, most countries are extremely short of SPMs and face serious supply risk Recovery of scattered and precious metals from copper 2016年1月1日 Copper concentrates may often contain significant levels of base and precious metal byproducts Copper smelters are efficient at recovery of gold, silver, and PGMs but often pay poorly and with much delay for these elements Base metals such as zinc, cobalt, and nickel are difficult to recover through a coppersmelter processCase Study Flowsheets: Copper–Gold Concentrate Treatment

.jpg)

The Gold Smelting Process Melting, Smelting Refining

2017年1月18日 The Amalgamation Process that employed mercury in the recovery of gold from the ore is no longer used at most major mines, but goldrich ore often has some traces of mercury that may still stick to gold even after the precipitation and the leaching process If not removed from the ore this mercury is likely to under volatilization during the NaOH preleaching is therefore concluded to be the most feasible process option based on low energy consumption and moderate recovery of gold Acknowledgments The authors acknowledge the funding and support of the Royal Society and African Academy of Sciences through the Future Leaders African Independent Researchers (FLAIR) grant FLR\ R1VL91541Evaluation of pretreatment methods for gold recovery from 2024年2月12日 This is the process of developing a gold smelter in Indonesia, capable of producing up to 50 tons per year In its implementation, smelters, of course, need to be balanced with implementing sustainable principles Therefore, cooperating with companies like Sucofindo, which provides comprehensive services, is the solutionThe Process of Gold Smelter Development in Indonesia2024年9月24日 tract gold In a modern gold processing plant, the recovery can be up to 98% with the aid of the latest concentration and smelting techniques A successful gold recovery strategy relies on a fundamental understanding of the ore mineralogy and its chemical/physical behaviors under various leach, flotation, and oxidation conditions An overview Processing technologies for goldtelluride ores 911 2005年1月1日 The goldcarrying arsenopyrite concentrate was shipped to a basemetal smelter for gold recovery The presence of active pyrrhotite may cause serious problems in gold cyanidation circuits, There are three important Brazilian plants using flotation to process gold ores (Monte et al, 2002) At the São Bento plant, gold and pyrite are floated Flotation of gold and goldbearing ores ScienceDirect2024年11月6日 Refining plays a vital role in the gold recovery process, as it enhances the purity of the recovered gold After gold is smelted, it often contains impurities or other metals, which must be removed to achieve a higher karat rating Refining methods can include chemical processes, electrolysis, and other techniques to separate gold from its Recycle Gold: A Comprehensive Guide to Gold Recovery

Reducing waste, increasing purity: The

2024年11月6日 Anode slime process is followed by copper smelter/refinery This batchoperated direct chloride leach process uses hydrogen peroxide as an oxidant Silver Recovery – Silver chloride residue from the gold recovery 2016年1月1日 The goldcarrying arsenopyrite concentrate was shipped to a basemetal smelter for gold recovery The presence of active pyrrhotite may cause serious problems in gold cyanidation circuits, There are three important Brazilian plants using flotation to Flotation of Gold and GoldBearing Ores ScienceDirectGold extraction – Wikipedia, the free encyclopedia Hard rock ores have formed the basis of the majority of commercial gold recovery Bulk leach extractable gold or BLEG, is also a process Gold smelting » Free online chat!smelter process for recovery of gold Grinding Mill China2016年1月1日 Pyrometallurgy emerges as a very promising, easy to adapt, and efficient route for recovery of the metallic fractions from WEEE In the scope of the present chapter, the application of pyrometallurgy in WEEE recycling, such as metallic components of cables, printed circuit boards (PCBs), cathode ray tubes (CRTs), liquid crystal display (LCD), and capacitors, Pyrometallurgical Processes for the Recovery of Metals from 2013年9月4日 In this paper, utilizing the existing primary copper smelter process for the recovery of metals from waste printed circuit boards (PCBs) is proposed as an alternative to the current backyard operations in developing countries The Model for Evaluating Metal Recycling Efficiency from Complex Scraps (MEMRECS) concept is introduced as a tool for the Improving sustainable recovery of metals from waste printed circuit 2024年9月19日 Among integrated smeltingconverting routes, the flash smelting to PeirceSmith converting route achieves the highest gold firstpass recovery (988–995%), followed by the Mitsubishi continuous (PDF) Gold Recovery from Smelting Copper Sulfide

Flowsheet Options For Processing Copper Gold Gold

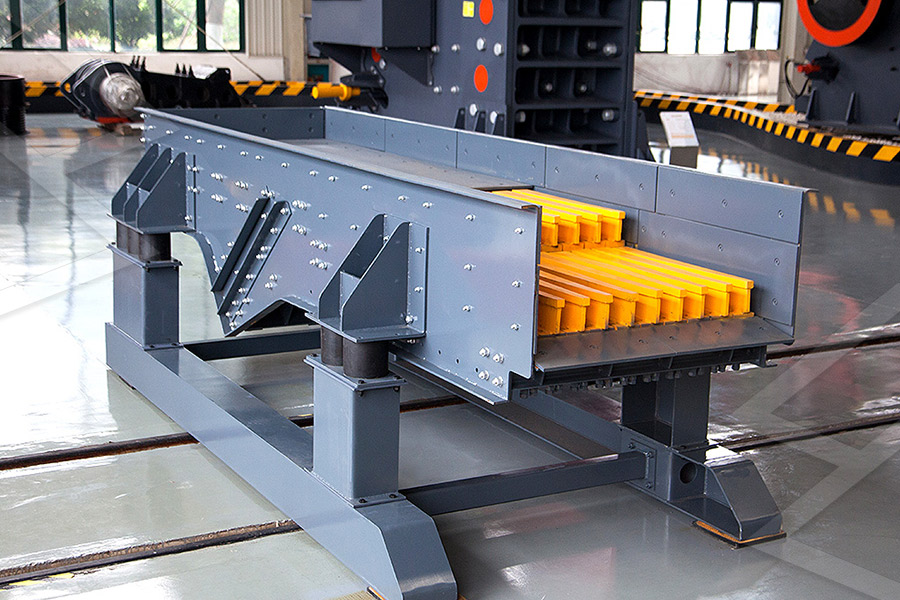

2024年5月14日 NSC process Copper and gold recovery Licencsed technology no details Pilotted but no commercial plants NO Escondida ammonia leach Copper and gold recovery Technical issues Not used NO Mt Gordon Chacocite ore only Limited application Mt Gordon plant NO 5 only Pressure oxidation Copper and gold 2015年1月12日 Anglo American PlatinumAnglo American Platinum2020年11月1日 An environmentalfriendly process for recovery of tellurium and copper from copper telluride Author links open overlay panel Liang Xu a b (Wang et al, 2003), and most of Chinese copper smelters like Tongling Nonferrous Metals Smelter and Zhongyuan Gold Smelter normally achieve the removal of tellurium from leaching solution of anode An environmentalfriendly process for recovery of tellurium 2019年3月20日 In order to recover gold and silver from anode slimes containing Cu, Ni, Sn, and Zn, an integrated hydrometallurgical process consisting of leaching, solvent extraction, and cementation was developed All the metals together with 10% of Ag(I) were dissolved by the mixture of HCl and H2O2 at the optimum conditions Separation of Au (III) together with Sn (II) Development of a hydrometallurgical process for the recovery of gold 2005年1月1日 This chapter discusses the recovery of gold as a byproduct from copper smelters and from the other base metal industries There are often platinumgroup metals (PGMs) that are also recovered as a component of the byproduct; more detailed discussion of gold recovery with PGMs may be found in Chapter 36, although Section 7 summarizes some direct leaching Recovery of gold as byproduct from the basemetals industries2018年3月22日 Mineable platinum group metal (PGM) deposits are rare and found in relatively few areas of the world At the same time, the use of PGM is predicted to expand in green technology and energy (PDF) Refining Approaches in the Platinum

.jpg)

Review of the Available Global Technologies for Gold

2021年10月20日 Extended residence of gold in side products between recovery steps Additional costs for utilisation of substantial amounts of middlings 12 Smelting with fluxes Smelting with fluxes is appropriate for processing zinc precipitates and lean goldsilver concentrates containing from 5% gold As a rule,2023年2月11日 This paper describes an innovative, fourstep, hydrometallurgical process for gold, palladium, platinum, selenium, and bismuth recovery and refining The combination of Au → Pd → Se → Bi in series is attractive for applications in major copper refineries where a fully hydrometallurgical process is chosen for anode slimes processingAn Innovative Hydrometallurgical Process for Recovery of 2024年12月7日 Gold is a significant revenue source for custom copper smelters facing profitability challenges due to low treatment and refining charges, stricter regulations, and rising costs Gold is also often blended with copper concentrates, but precise recovery rates from smelting processes are poorly documented despite gold critical economic importance This Gold Recovery from Smelting Copper Sulfide Concentrate2019年6月18日 The limitation of this process in the smelter plant is gi ven by the final metal lic phase to be obtained, which must be recycled t o the process, and this phase must be clean of iron so as to (PDF) Metallurgical Processing Strategies for Metals Recovery waste copper slag This process is simpler than conventional pyrometallurgical process as the addition of any external collectors are not required47 Hydrometallurgy Metal separation and recovery using hydrometallurgical processes have lower capital cost and environmental impact than pyrometallurgy, and offer greater scope for selective metalChallenges and opportunities in the recovery of gold Gold processing Refining, Smelting, Purifying: Gold extracted by amalgamation or cyanidation contains a variety of impurities, including zinc, copper, silver, and iron Two methods are commonly employed for purification: the Miller process and the Wohlwill process The Miller process is based on the fact that virtually all the impurities present in gold combine with Gold processing Refining, Smelting, Purifying Britannica

.jpg)

Refining of Gold at the Rand Refinery 911 Metallurgist

2024年9月24日 Chamber of Mines investigated the possibility of establishing a local gold refinery The technical aspects were discussed with Sir TK Rose, a leading authority on gold metallurgy, and the chlorine refining process was chosen specifically with a view to the rapid and effective treatment of large amounts of bullion2021年11月2日 process 33 Gold and Silver Deportment in CESL Copper Process Gold and silver generally do not leach in the CESL Copper Process, and are therefore left almost quantitatively in the residue after recovery of base metals Thus any recovery process for gold and silver must be an additional or subsequent step(s) processing suchTHE NEW CESL GOLD PROCESS Teck Resources2017年9月7日 At current gold prices this is worth about US$600 Both smelter treatment charges and oxidation or bioleach costs are at least $200/t of concentrate and payables/recovery in the 90% range, so a minimum GSR for Gold processing 101 Mining Magazine2020年11月1日 The mineral resources containing SPMs are of many types and variable grade, resulting in high mining and utilization costs (Işıldar et al, 2017; Rana et al, 2020)Further, > 99% of these resource exist in only a few countries, such as South Africa and Canada (Zhang et al, 2017a)As a result, most countries are extremely short of SPMs and face serious supply risk Recovery of scattered and precious metals from copper 2016年1月1日 Copper concentrates may often contain significant levels of base and precious metal byproducts Copper smelters are efficient at recovery of gold, silver, and PGMs but often pay poorly and with much delay for these elements Base metals such as zinc, cobalt, and nickel are difficult to recover through a coppersmelter processCase Study Flowsheets: Copper–Gold Concentrate Treatment2017年1月18日 The Amalgamation Process that employed mercury in the recovery of gold from the ore is no longer used at most major mines, but goldrich ore often has some traces of mercury that may still stick to gold even after the precipitation and the leaching process If not removed from the ore this mercury is likely to under volatilization during the The Gold Smelting Process Melting, Smelting Refining

.jpg)

Evaluation of pretreatment methods for gold recovery from

NaOH preleaching is therefore concluded to be the most feasible process option based on low energy consumption and moderate recovery of gold Acknowledgments The authors acknowledge the funding and support of the Royal Society and African Academy of Sciences through the Future Leaders African Independent Researchers (FLAIR) grant FLR\ R1VL915412024年2月12日 This is the process of developing a gold smelter in Indonesia, capable of producing up to 50 tons per year In its implementation, smelters, of course, need to be balanced with implementing sustainable principles Therefore, cooperating with companies like Sucofindo, which provides comprehensive services, is the solutionThe Process of Gold Smelter Development in Indonesia2024年9月24日 tract gold In a modern gold processing plant, the recovery can be up to 98% with the aid of the latest concentration and smelting techniques A successful gold recovery strategy relies on a fundamental understanding of the ore mineralogy and its chemical/physical behaviors under various leach, flotation, and oxidation conditions An overview Processing technologies for goldtelluride ores 911 2005年1月1日 The goldcarrying arsenopyrite concentrate was shipped to a basemetal smelter for gold recovery The presence of active pyrrhotite may cause serious problems in gold cyanidation circuits, There are three important Brazilian plants using flotation to process gold ores (Monte et al, 2002) At the São Bento plant, gold and pyrite are floated Flotation of gold and goldbearing ores ScienceDirect2024年11月6日 Refining plays a vital role in the gold recovery process, as it enhances the purity of the recovered gold After gold is smelted, it often contains impurities or other metals, which must be removed to achieve a higher karat rating Refining methods can include chemical processes, electrolysis, and other techniques to separate gold from its Recycle Gold: A Comprehensive Guide to Gold Recovery