Beneficiation Plant For Manganese

.jpg)

Manganese Beneficiation Processing

2022年5月27日 At present, the commonly used beneficiation methods of manganese ore are mechanical beneficiation (including ore washing, screening, gravity separation, highintensity magnetic separation and flotation), fire 2025年4月2日 Manganese ore beneficiation technology is used to extract manganese from manganesecontaining ores It mainly includes crushing and grinding, gravity separation, magnetic separation, flotation or combined Five Kinds Technology Of Manganese Ore Strong magnetic rough selection First, a special strong magnetic separator for manganese ore is used to initially remove impurities from manganese ore, and the coarseselected concentrate Manganese ore beneficiation plant xkjgroup2024年8月8日 Manganese Ore Beneficiation Plant Manganese is one of the most commonly used metals in the world Mainly used as an additive in steel production, it is an essential raw Manganese Ore Beneficiation PlantKefid MachineryEnhance manganese ore quality for optimal performance in alloy production Manganese ore plays a crucial role in alloy production, particularly in the creation of ferromanganese – an alloy composed of manganese and iron, containing Manganese Ore Beneficiation CFlo2025年4月3日 Manganese ore beneficiation is extracting valuable minerals and removing impurities from manganese ore It usually includes crushing, grinding, washing, gravity separation, flotation or magnetic separation process to Manganese Ore Processing Plant, Manganese

.jpg)

Manganese Ore Beneficiation Plant CM Mining Machinery

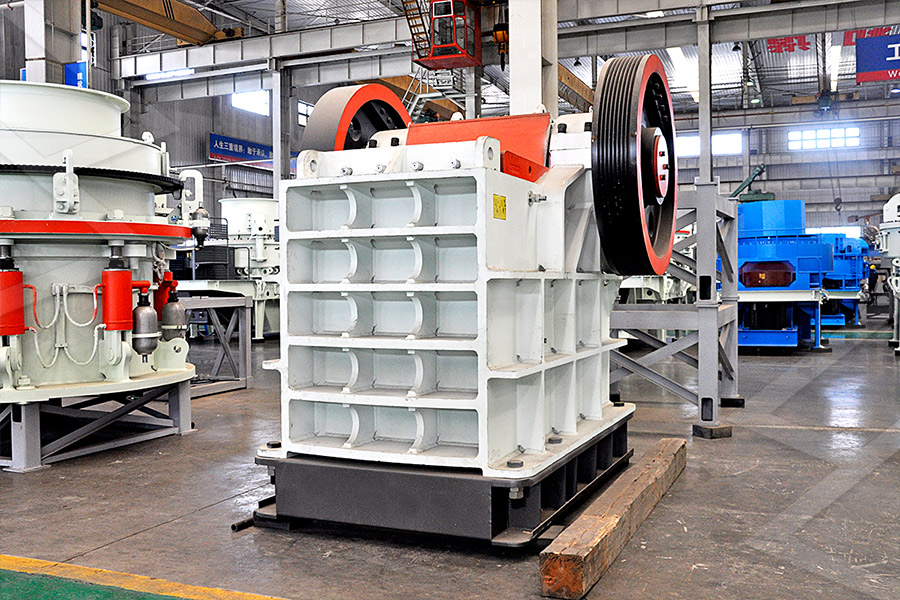

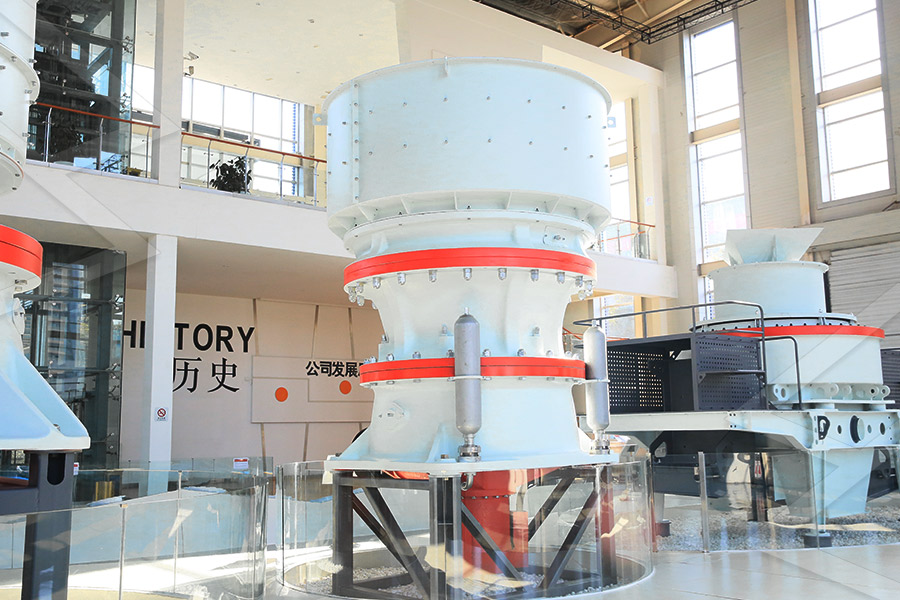

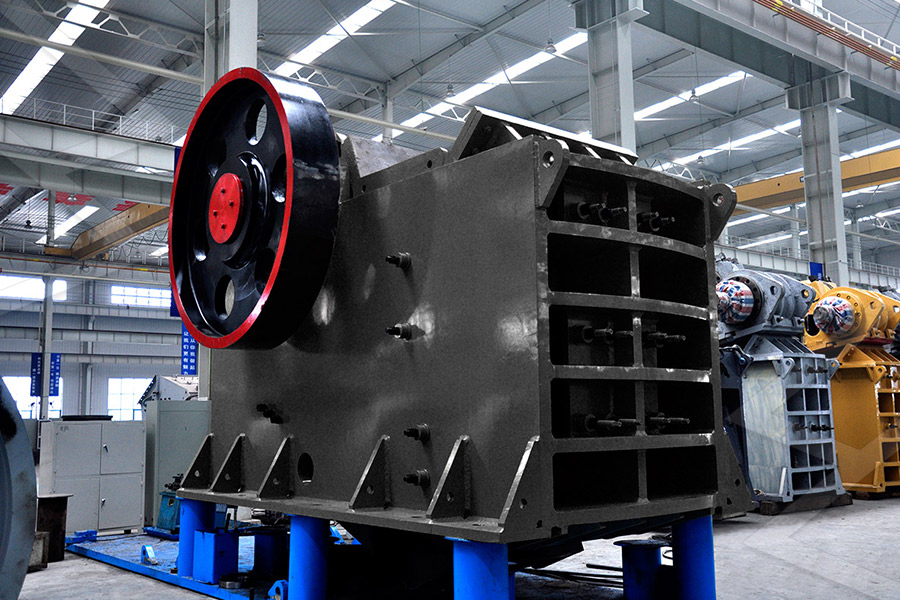

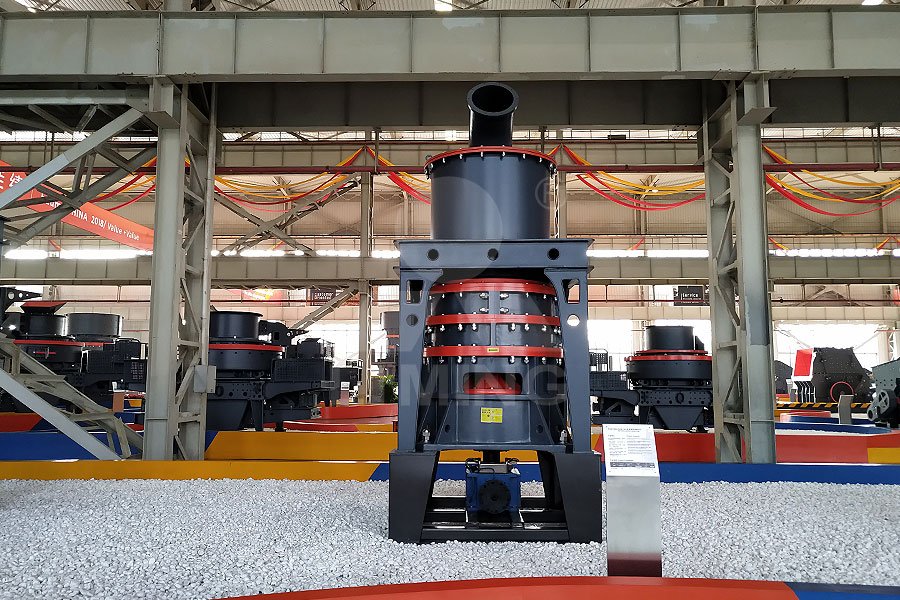

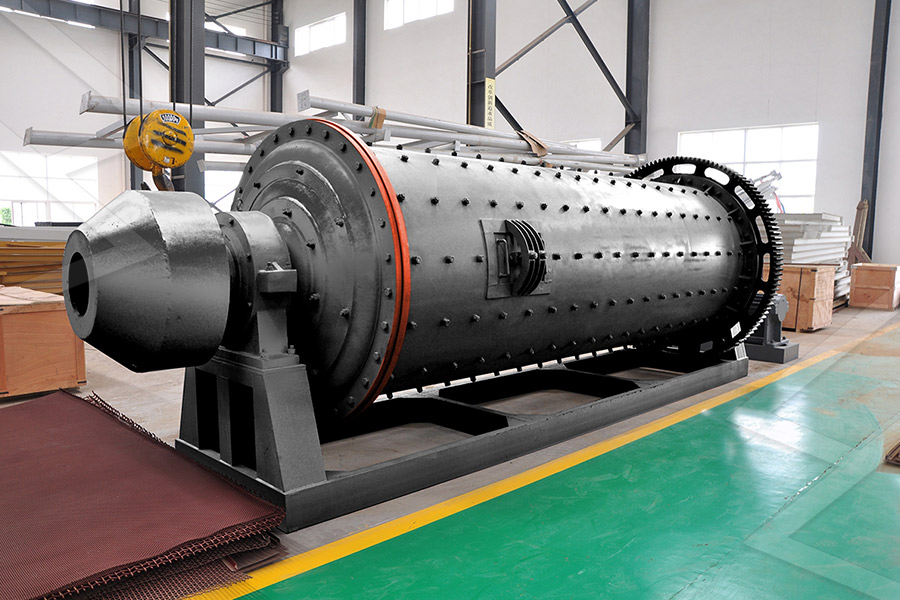

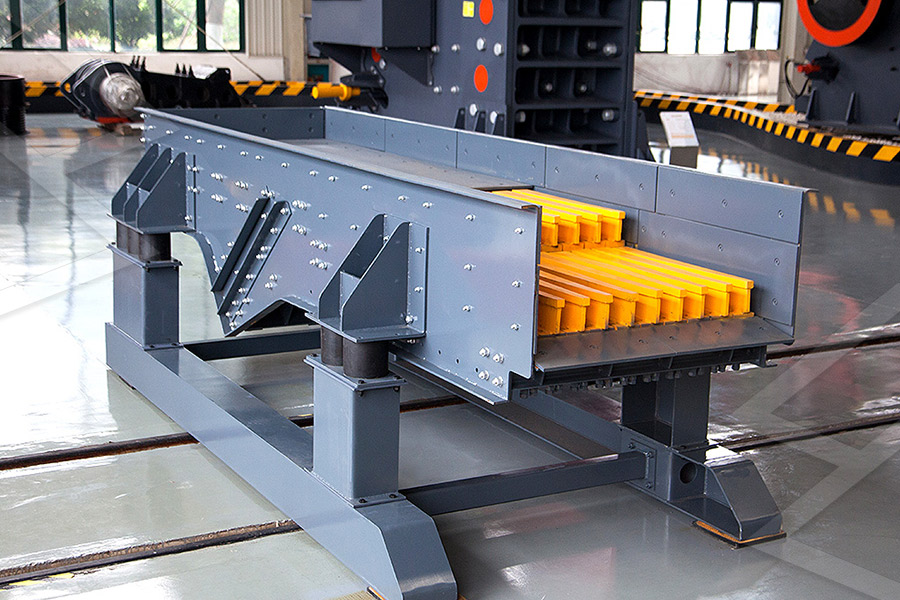

Based on these differences, the suitable processing plant for manganese ore is the mechanical selection (including washing, sieving, reelection, strong magnetic separation and flotation), as 3 天之前 Includes iron ore, manganese, chrome, limonite, titanium, hematite, magnetite, and other ore processing plant solutions It’s mainly extract iron ore from minerals and separates valuable ore JXSC has experienced Mineral Processing Plant Beneficiation 2023年8月7日 The beneficiation machines for manganese ore mainly include vibrating feeders, jaw crushers, fine jaw crushers, conveyors, swing feeders, ball mills, (weak, medium, strong) magnetic separators, jig separators, ore Five Common Types Of Manganese Ore 2021年9月23日 Commonly used manganese ore beneficiation methods are mechanical beneficiation, including ore washing, screening, gravity separation, strong magnetic separation, and flotation Sometimes pyrometallurgy MANGANESE ORE BENEFICIATION 2020年5月6日 too steep for manganese ore, forcing most of the mines to close down during the slump periods PUTTING UP BENEFICIATION PLANTS Next comes the most important method for conservation of manganese ores, namely putting up of beneficiation plants to treat the lowgrade ores as well as rejects obtained after handpicking ThisManganeseore Beneficiation Plants for India2025年4月2日 A key aspect of manganese ore processing is the efficient removal of impurities through beneficiation processes such as gravity, magnetic, or flotation Manganese ore processing plants can optimize filtration and dewatering processes and increase overall productivity while minimizing environmental impact through responsible water management Equipment Required To Build A Manganese Ore Processing Plant

Manganese Ore Beneficiation Plant FTM Machinery

2025年3月28日 As manganese ore is lowgrade, containing phosphate ore, iron ore and associated metals, it is not easy to separate Therefore, the efficient and economical separation of manganese ore is crucial The manganese ore beneficiation plant aims to produce manganese concentrates of various grades to maximize manganese recovery most economically2016年9月12日 Azul is the biggest Brazilian manganese mine which has been in operation since 1985 and the manganese processing plant consists of crushers, scrubbers, screens, and a spiral classifier to remove (PDF) BENEFICIATION OF LOW GRADE MANGANESE ORE BY 2022年5月27日 The commonly used beneficiation methods of manganese ore are gravity and magnetic separation, flotation, chemical beneficiation, etc in 1962, the Shanghai ferroalloy plant and Shijingshan iron and steel plant smelted manganeserich slag in blast furnaces respectively In 1975, the Hunan Manaoshan manganese mine blast furnace not only Manganese Beneficiation Processing Technology in China2022年8月19日 The manganese content of this manganese ore is very high, the upper limit of the selected particle size is 4075mm, simple manganese ore beneficiation methods can be separated, and high quality Five Common Types of Manganese Ore Beneficiation 2017年10月6日 South Africa’s first pilot plant in manganese beneficiation will be launched in Nelspruit on Wednesday, 11 October, as a strategic development programme responding to the fast pace evolution of rechargeable battery technology in the countryMinister Pandor to launch pilot plant for manganese beneficiation Manganese Beneficiation Plant in South Africa5 The beneficiation methods of manganese ore include gravity beneficiation method, magnetic separation method and flotation method, but the most widely used one is gravity Manganese Ore Processing Line Henan Forui

.jpg)

A global life cycle assessment of manganese mining

2019年10月20日 This paper presents the life cycle assessment (LCA) carried out on the manganese beneficiation and refining process This cradletogate analysis is carried out using SimaPro software version 85 The considered case is the manganese beneficiation and refining process, and the final product is 1 kg of refined manganese2024年4月26日 2 Beneficiation Beneficiation is the process of separating ironbearing minerals from the gangue minerals and removing impurities to improve the iron grade and quality of the ore Various techniques are employed based Iron Ore Processing: From Extraction to The manganese processing plant from allmineral now provides a throughput of 200 tons per hour, with our system solution enabling a material yield of over 68% This high level of performance is ensured by sophisticated wet processing and highgradient magnetic separation: first, two alljig ® jigs at the heart of the plant are responsible for allmineral – efficient manganese ore mining allmineral Name of the Project/s: Narayanposhi Iron and Manganese Ore Mine of M/s JSW Steel Ltd for production of 10 million TPA (ROM) of Iron ore with total excavation of 10815 million TPA (ROM 10 MTPA + OB 0815 MTPA) and 0036 million TPA of Manganese ore (ROM) with total excavation of 03059 million TPA (ROM 0036 MTPA + OB 0269 MTPA) along with screening, Report Part 1 environmentclearancenic2020年6月19日 plant in the EL IDZ –supported by the IDC The plant will process vanadium oxide from South Africa and use other locally manufactured reagents (eg sulphuric acid) Plan to start production by end of 2020 Precursor for vanadium redox flow batteries 25 000 tpa pure nickel sulphate plant supported by the Black Industrialist ProgrammeMINERAL BENEFICIATION thedticgov2024年8月8日 Manganese Ore Beneficiation Plant Manganese ore beneficiation process has many large and small equipment: vibrating feeder, PE jaw crusher, JC jaw crusher, HJ jaw crusher, vibrating screen, electromagnetic vibrating feeder, ball mill, spiral classifier, hydrocyclone, high frequency screen, magnetic separator, jigger, mixing barrels, flotation Manganese Ore Beneficiation PlantKefid Machinery

.jpg)

Manganese Processing Equipment, Process Flow, Cases JXSC

2019年8月23日 Most manganese ore is a finegrain, and contains phosphorus ore, iron ore and associated minerals, which brings a great difficulty to beneficiation processing At present, the commonly used manganese ore beneficiation methods are mechanical beneficiation methods (washing, screening, gravity separation, strong magnetic separation and flotation Abstract Big producers with large orereserves should put up their own beneficiation plants But, since majority of the manganese mines are small producers and have only medium or smal! orereserves, and since about 50% of the manganese ores of India are of a complex nature requiring elaborate treatment, erection of custom type mills is the best way to their upgrading and Manganeseore Beneficiation Plants for India eprints@NML2019年12月13日 Integrated Manganese Beneficiation Plant A s a part of mechanization of ore handling and beneficiation of manganese ore, the Company has set up an integrated Manganese Ore Beneficiation Plant comprising of crushing, handling, wet screening, drying and magnetic separation operations in one complex at a capital cost of Rs4 crores, in 2001Manganese Ore (india) Limited MOIL2019年9月21日 Feasibility and Costing for Setting up a Manganese Ore Beneficiation Plant In May, 2017, we successfully installed a manganese ore beneficiation plant in Oman for customer called Kubar and following comes Feasibility and Costing for Setting up a Mica Ore Beneficiation Plant : Mica Ore beneficiation Plants turnkey solution is provided by Star Trace We are one of the leading project suppliers for Mica Ore Beneficiation Plant and we work closely with our customers to fulfil their Iron Ore benefication Plants Mica Ore 2022年9月27日 The Khondbond Iron Manganese Mine with the processing plant, the iron and manganese mine pits are separately been operated The processing plant is under construction and shall be of zero effluent discharge unit; all the effluent generated from the processing of iron ore is collected from slime pond and recycled ENVIRONMENT STATEMENT Tata Steel

.jpg)

Beneficiation of Iron Ores IspatGuru

2014年4月3日 Fig 1 Typical flowsheet of ore beneficiation plant Several methods / techniques such as washing, jigging, magnetic separation, gravity separation, and flotation etc are used to improve the Fe content of the iron ore and to reduce its gangue content These techniques are used in different combinations for the beneficiation of iron oresGEMCO Manganese (NT) GEMCO is located on Groote Eylandt in the Northern Territory, Sedgman completed the detail design of the sands beneficiation plant and earthworks for the stockpile containment shed, loop road, associated drainage works Modular Plant Design Sedgman2018年12月9日 beneficiation of mineral commodities mined in South Africa It recognises that beneficiation should: • Be considered on a valuechain by valuechain basis, • Be geared towards higher levels of employment intensity and valueaddition, and • Take into account infrastructure considerations (such as energy and water availability) Beneficiation strategy for minerals industry in South Africa2019年7月29日 The main manganese oxide ore beneficiation plants such as those found in GEMCO in Australia (Groote Eylandt Mining Company, part of the South 32 group) and COMILOG in Gabon (part of the Eramet A Review of Low Grade Manganese Ore Upgradation Processes2019年4月3日 Manganese Ore Beneficiation Plant 1 Manganese ore overview Manganese ore is widely used in steel, nonferrous metallurgy, chemical, electronics, battery, agriculture, etc industry More than 90% of the world’s manganese is used in the steel industry Global terrestrial manganese ore reserves are 6 800 million tons (manganese metal), most Manganese Ore Beneficiation Manganese Ore Processing Plant on manganese ore beneficiation and agglomeration The research work conducted in reputed laboratories like IBM, NML, NMDC, RRLS, CSIR labs and various engineering colleges is highly significant In fact there is hardly any manganese ore deposit in India, which has not been investigated impossible to set up a small beneficiation plant at HWVRLJQRUHG IOPscience

.jpg)

Beneficiation of low grade manganese ore fines

2012年9月7日 ferromanganese and metal in steelmaking Manganese ore is mined by both underground and surface methods depending upon the geological setting of the deposits The manganese ore is usually hand sorted into lump ore and fines The manganese content in the lump ore is higher compared to that of the fines At present, the manual sizing and sorting of3 天之前 Includes iron ore, manganese, chrome, limonite, titanium, hematite, magnetite, and other ore processing plant solutions It’s mainly extract iron ore from minerals and separates valuable ore JXSC has experienced Mineral Processing Plant Beneficiation 2023年8月7日 The beneficiation machines for manganese ore mainly include vibrating feeders, jaw crushers, fine jaw crushers, conveyors, swing feeders, ball mills, (weak, medium, strong) magnetic separators, jig separators, ore Five Common Types Of Manganese Ore 2021年9月23日 Commonly used manganese ore beneficiation methods are mechanical beneficiation, including ore washing, screening, gravity separation, strong magnetic separation, and flotation Sometimes pyrometallurgy MANGANESE ORE BENEFICIATION 2020年5月6日 too steep for manganese ore, forcing most of the mines to close down during the slump periods PUTTING UP BENEFICIATION PLANTS Next comes the most important method for conservation of manganese ores, namely putting up of beneficiation plants to treat the lowgrade ores as well as rejects obtained after handpicking ThisManganeseore Beneficiation Plants for India2025年4月2日 A key aspect of manganese ore processing is the efficient removal of impurities through beneficiation processes such as gravity, magnetic, or flotation Manganese ore processing plants can optimize filtration and dewatering processes and increase overall productivity while minimizing environmental impact through responsible water management Equipment Required To Build A Manganese Ore Processing Plant

Manganese Ore Beneficiation Plant FTM Machinery

2025年3月28日 As manganese ore is lowgrade, containing phosphate ore, iron ore and associated metals, it is not easy to separate Therefore, the efficient and economical separation of manganese ore is crucial The manganese ore beneficiation plant aims to produce manganese concentrates of various grades to maximize manganese recovery most economically2016年9月12日 Azul is the biggest Brazilian manganese mine which has been in operation since 1985 and the manganese processing plant consists of crushers, scrubbers, screens, and a spiral classifier to remove (PDF) BENEFICIATION OF LOW GRADE MANGANESE ORE BY 2022年5月27日 The commonly used beneficiation methods of manganese ore are gravity and magnetic separation, flotation, chemical beneficiation, etc in 1962, the Shanghai ferroalloy plant and Shijingshan iron and steel plant smelted manganeserich slag in blast furnaces respectively In 1975, the Hunan Manaoshan manganese mine blast furnace not only Manganese Beneficiation Processing Technology in China2022年8月19日 The manganese content of this manganese ore is very high, the upper limit of the selected particle size is 4075mm, simple manganese ore beneficiation methods can be separated, and high quality Five Common Types of Manganese Ore Beneficiation 2017年10月6日 South Africa’s first pilot plant in manganese beneficiation will be launched in Nelspruit on Wednesday, 11 October, as a strategic development programme responding to the fast pace evolution of rechargeable battery technology in the countryMinister Pandor to launch pilot plant for manganese beneficiation